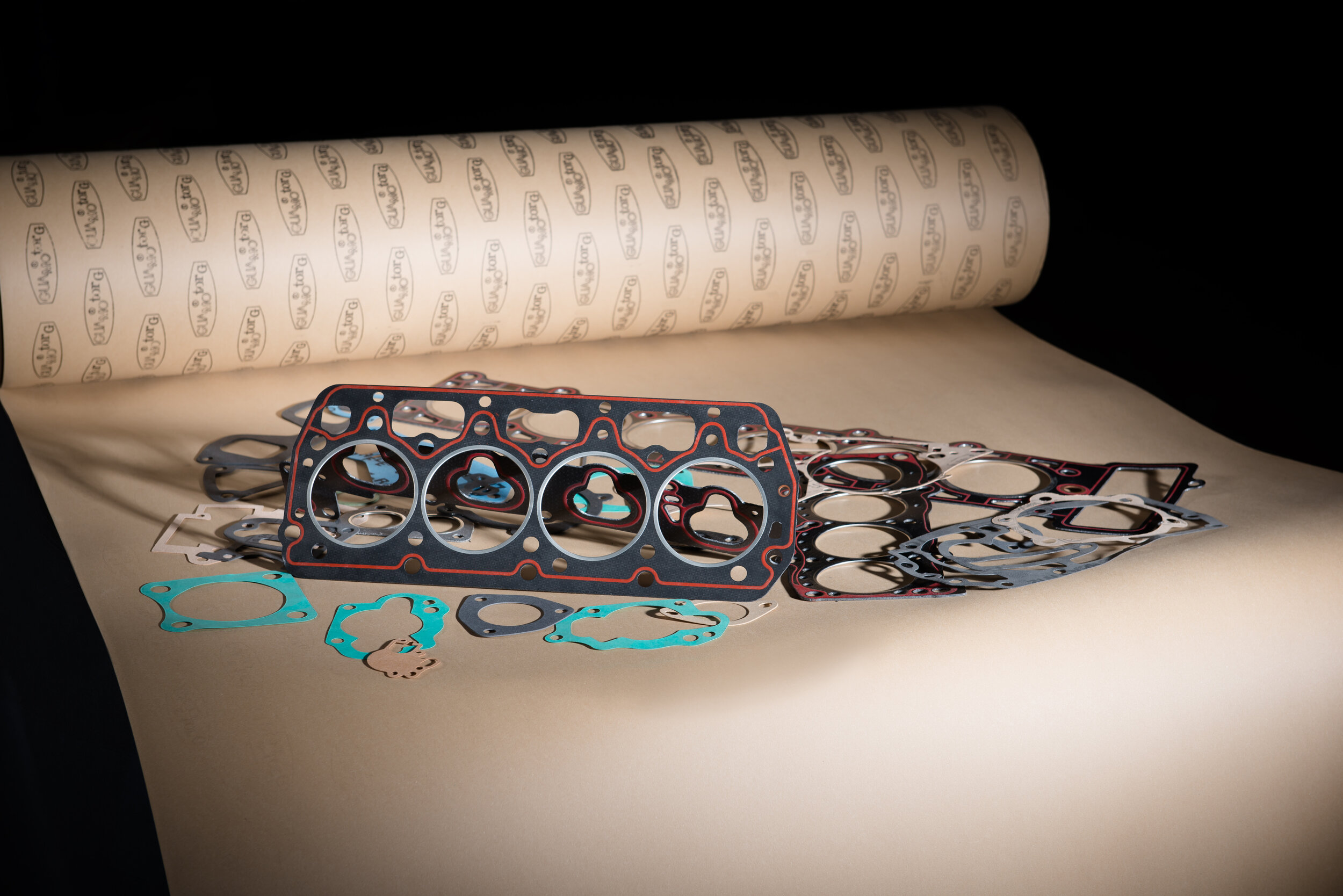

Asbestos FREE since ALWAYS, through decades we developed custom made materials for every market needs, offering now one of the widest material selection in the market. Our technical Team, loyally dedicates its professional skills and advanced R&D technologies, to help our customers to find the most appropriate match between product design and market needs. We believe it is essential to have a reliable experienced partner for creating mutually beneficial sealing solutions, without overdesigned driven selection. This “Customer tailoring” proven philosophy will continue to drive our mutual success and longevity in worldwide sealing market.

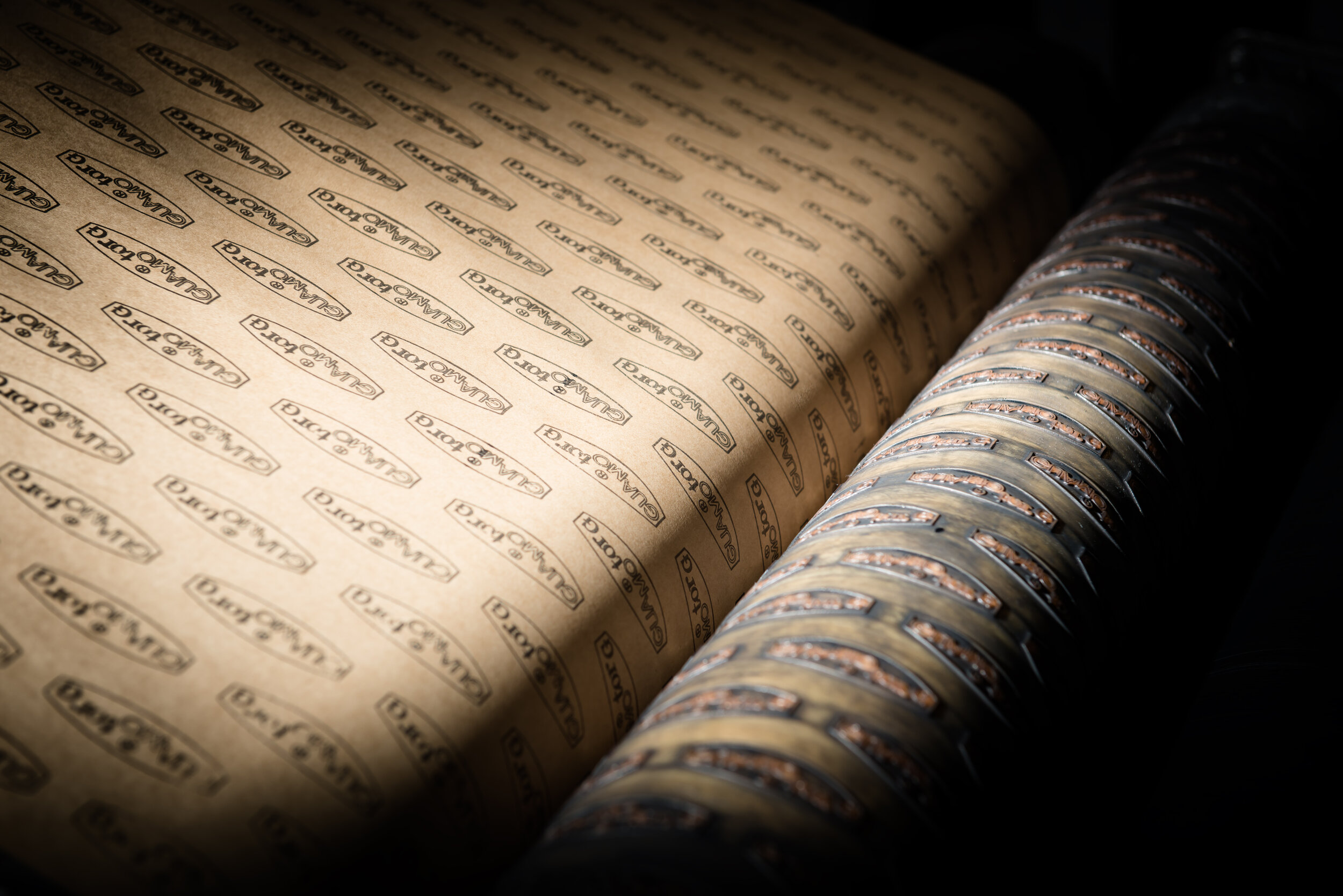

Fiber materials: our KH combines formulations and technologies to provide over 50 different materials . Our flexible business approach in the industry through decades, brought our structure (R&D, equipment, management and team) to achieve important skills in the sealing industry, mentioning few as example:

Uniform distribution of flange pressure resulting from superior distribution of material composition;

Close tolerance thickness

Improved sealability at low-flange pressure;

Greater crush resistance by design;

High temperature KH

Manufacturing Quality at every step, using operator level Statistical Process Control tools;

Competitive and stable pricing

Custom printing

Fiber sealing: as one of first worldwide producers of non asbestos fiber materials, Omnia is recognized as a reference producer in this field. Since ever non asbestos material producers, we dedicate our longtime developed skill to gasket makers.

beading silicone compatible

thickness range from 0,2mm to 1,5mm

antistick coatings

top DIN 52913 Creep performances

NEW Grafonit (flexible expanded graphite equivalent)

Metal Fiber: as a leading producer of facing material, our composite technology offers one of the widest and most competitive range of high performance Metal/fiber laminates, to properly support applications at extreme conditions.

Perforated metal core: our design grants a very high density perforation, ensuring a better bond of facing to metal. Our wide range of facing materials, ensure multitude options of final assemblies:

Different densities allows good recovery, ensuring greater sealing performances also at lower torque.

One of the widest thickness availabilities: from 0,6mm to 3,0mm

Custom design sandwich combination

Solid metal core: according to final application, we select the best material to be bonded to metal. Chemical resistance to most used fluids, always assure perfect bonding.

From 0,50 to 3,0mm our materials ensure perfect sealing also at lower Torque bolt pressions.

In Aftermarket, cylinder head flanges are no more perfectly flat and RMCS cannot assure same performances as in OEM. Aftermarket requires a more adaptable material to properly seal Cylinder Head high performance requirements.

Graphite metal: excellent pressure/temperature resistance, Grafpack keeps sealing abilities at over 1000F. Cylinder head, exhaust, intake manifold, turbo chargers, often used graphite, our equivalent graphite based material ensure high performances at competitive price, always sulphur free.

Heat shielding: Increasing use of energy as well as more and more compressed engines develop unwanted heat that needs to be controlled. Omnia has long experience in non asbestos high temperature materials. Today we can offer a wide range of competitive materials that insulate or defuse heat.